Anticipation Grows:

Monday 20th June 2016

Extra builders are due on-site next week to put the timber LVL roof rafters up. So begins an all out effort by Nino and his amateur help, to ensure that there is an outside wall, and a fixing batten in the “C” section of the box gutter’s steel frame to fix these LVL bearers to.

Wednesday 22nd June 2016

To maintain the 5° pitch of the roof, as the outside walls get further from the “point to point centre line” ( at the mid point of the house the outside walls are 5.5m from the centre) they must naturally get higher. When cutting the wall studs, a 2° angle was required to give this continuous rise, as can be seen below.

Nino & “Lynchie”

At each end of the building there are lots of fiddly framing bits to measure, cut, and sometimes the need to chisel around protruding bolts from the steel. Time consuming mainly, but then the whole build requires a lot more time than the normal straight square home.

Not complainin’,…. Just sayin’ like….

Eastern end

The other end, not finished.

Friday 24th June

Yikes.

Nino (I think it is) in disguise, he says “because it is sooo cold!” I think it was to hide his identity as he told the story of the Wild Turkey who went into a bar…

The barman says: ” Hi there, do you know that we have a whiskey named after you?

The Wild Turkey looks at him and says: “What? Kevin?

Another week of wall framing has passed with some definition of a few rooms starting to take shape as they are closed in by the wall frames.

View form the ensuite shower

Where the Larger feature windows are we made the frames as one piece so the large panes of glass are installed as one piece and not broken into two or three smaller windows. This will require packing as can be seen in the picture below.

Packing required to round the outside profile under this feature window

35mm x 90mm timber battens were bolted to the “C” section of the steel box gutter support, and the opportunity was taken to also bolt on some 35mm x 90mm timber across underneath so as to enable a framework for producing a gradient in the gutter.

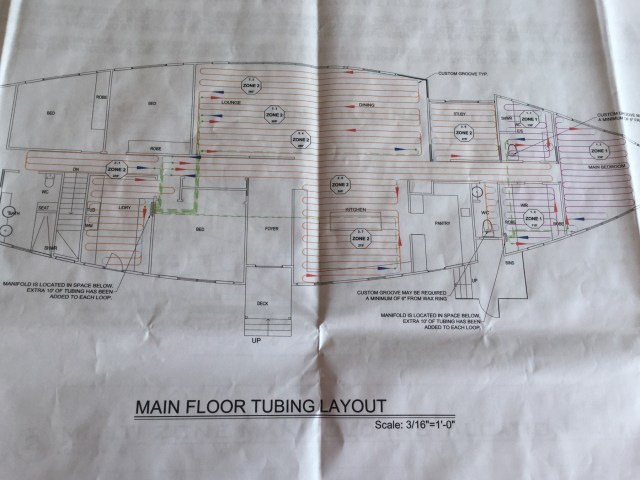

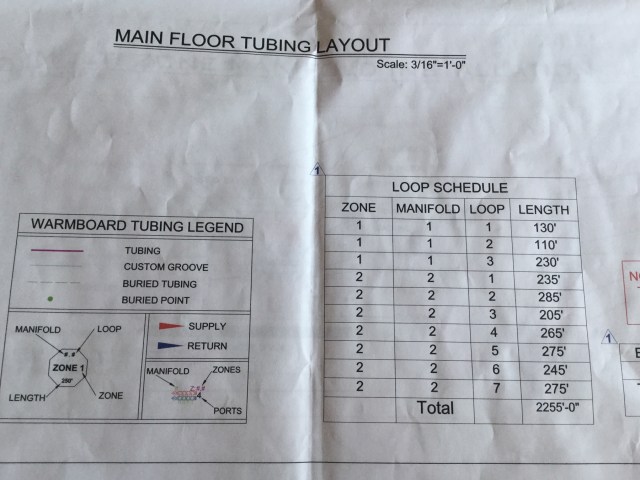

We also need to make our first custom rout in the Warmboard before the ensuite bottom wall plate goes down so as to have room for the router to do it’s business. The pex tubing comes out of the passage into the ensuite and exits back into the passage to continue on to the manifold.We will route it through a doorway, (as drawn on our plans by the Warmboard designers ) but need to do it now as there will not be enough room for the router to work once the wall plate is down. With the router and bit kindly loaned to us by Peter Taylor of Australian Sun Energy and the templates which come with the warmboard package, Nino set about discovering how hard or easy this could be.

Our first custom rout..

All Good. No major dramas, although we found the bit that came with the router was fairly well used and a bit blunt and for some reason it was hard to get enough depth with it. We pulled the bit out of the chuck as far as we dared and used all the depth adjustment available on the router to achieve the right depth for the pex to fit flush into the groove.

Only after, did we discover there was a brand new bit with the templates in the router packaging supplied by Warmboard. Next Time!

Saturday Morning 25th June:

Extra help arrives.

The two extra builders. Jarrod and Toby, arrived this morning amidst the clearing rain showers. They too have been held up with rain on their previous job, but are all set to make up for lost time.

By the afternoon, …. steaming ahead.

Rafters appear on the skyline

Hopefully a good week of fine weather and plenty of construction to follow, with a third extra “chippie” to arrive on Wednesday I think.